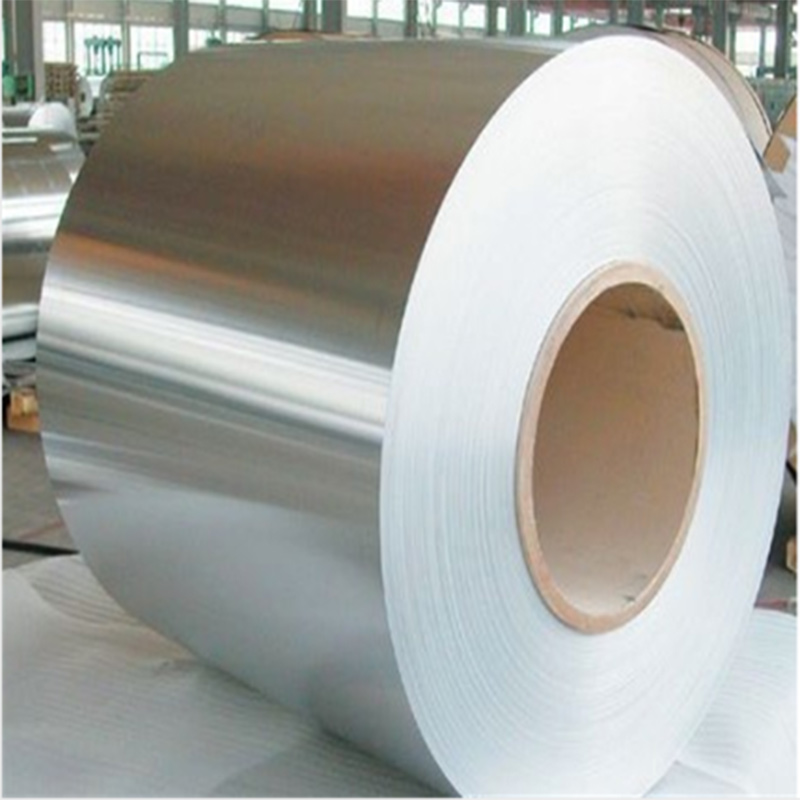

316 coil stainless steel

Katerangan

Bahan:201, 202, 301, 302, 304, 304L, 310, 310S, 316, 316L, 321, 409, 410, 420, 430 jeung bahan séjén.

spésifikasi:Kandel 0,03 mun 5.0mm lebar bisa motong sabuk baja, sabuk ipis, roll sabuk, calendering sabuk jeung strip séjén (catetan: nurutkeun produksi paménta customer rupa ketebalan sarta rubak sabuk calendering stainless steel).

Beungeut:permukaan BA, beungeut 2B, NO.1 (kulit bodas), beungeut 2D, NO.4 (taneuh), HL (brushed), kualitas permukaan 8K, rupa bahan kacaangan alus: sabuk stainless steel, sabuk conveyor stainless steel, packing stainless steel sabuk, sabuk stainless steel elastis, sabuk coil stainless steel, sabuk stainless steel ultra-ipis.

Teu karasa:(HV) 160 ° -600 ° (lemes, 1 / 2h, 3 / 4h, H) jeung kelas dua sabuk coil stainless steel séjén.

Catetan:pikeun mastikeun eusi nikel strip stainless steel sarta sipat mékanis tina strip stainless steel, urang bisa nyadiakeun sertipikat bahan (bahan Baosteel), sertipikat bahan Nippon Steel (bahan baja Nippon), laporan SGS, jsb.

Masalah Anti korosi

316 nyaeta stainless steel ngandung molybdenum.Dina kaayaan suhu luhur, nalika konsentrasi asam sulfat handap 15% na luhur 85%, 316 stainless steel boga rupa-rupa aplikasi.

316L stainless steel boga eusi karbon maksimum 0,03 sarta bisa dipaké dina aplikasi mana annealing sanggeus las teu mungkin jeung dimana lalawanan korosi maksimum diperlukeun.

Résistansi korosi

lalawanan korosi leuwih hade tinimbang 304 stainless steel, dina prosés produksi bubur jeung kertas boga lalawanan korosi alus.Jeung 316 stainless steel oge tahan ka Kelautan jeung atmosfir industri agrésif.

Tahan panas

Dina pamakéan discontinuous handap 1600 derajat sarta dina pamakéan kontinyu handap 1700 derajat, 316 stainless steel boga résistansi oksidasi alus.Dina rentang 800-1575 derajat, leuwih sae pikeun henteu terus-terusan ngagunakeun 316 stainless steel, tapi dina rentang hawa di luar pamakéan kontinyu tina 316 stainless steel, nu stainless steel ngabogaan résistansi panas alus.316L stainless steel boga résistansi présipitasi carbide hadé ti 316 stainless steel sarta bisa dipaké dina rentang suhu luhur.

spésifikasi: 0.6-16 mm Bahan: 316L Asal / produsén: domestik, diimpor.

Parameter

| Ngaran Produk | 304 2B Stainless Steel Coil |

| Panjangna | Sakumaha diperlukeun |

| Lebar | 3mm-2000mm atawa sakumaha diperlukeun |

| Kandelna | 0.1mm-300mm atawa sakumaha diperlukeun |

| Standar | AISI, ASTM, DIN, JIS, GB, JIS, SUS, EN, jsb. |

| Téhnik | Hot rolled / cold rolled |

| Perlakuan permukaan | 2B atawa nurutkeun sarat customer |

| Kasabaran ketebalan | ± 0,01 mm |

| Bahan | 201, 202, 301, 302, 303, 304, 304L, 304H, 310S, 316, 316L, 317L, 321,310S 309S, 410, 410S, 40,40, 40, 43 |

| Aplikasi | Hal ieu loba dipaké dina aplikasi suhu luhur, alat médis, bahan wangunan, kimia, industri pangan, tatanén, komponén kapal. Ieu ogé lumaku pikeun kadaharan, bungkusan inuman, suplai dapur, karéta, pesawat, belts conveyor, kandaraan, bolts, kacang, cinyusu, jeung layar. |

| MOQ | 1tons.We ogé bisa nampa urutan sampel. |

| waktos pangiriman | Dina 15-20 workdays sanggeus narima deposit atawa L / C |

| Ékspor bungkusan | kertas waterproof, sarta strip baja packed.Standard Ékspor Seaworthy Package.Suit pikeun sagala jinis angkutan, atawa sakumaha diperlukeun |

| Kapasitas | 250.000 ton/taun |

| Sipat Kimia tina Kelas Bahan Stainless Steel anu sering dianggo | |||||||||||

| UNS | ASTM | EN | JIS | C% | Mn% | P% | S% | Si% | Cr% | Ni% | Mo% |

| S20100 | 201 | 1.4372 | SUS201 | ≤0.15 | 5.5-7.5 | ≤0.06 | ≤0.03 | ≤1.00 | 16.0-18.0 | 3.5-5.5 | - |

| S20200 | 202 | 1.4373 | SUS202 | ≤0.15 | 7.5-10.0 | ≤0.06 | ≤0.03 | ≤1.00 | 17.0-19.0 | 4.0-6.0 | - |

| S30100 | 301 | 1.4319 | SUS301 | ≤0.15 | ≤2.00 | ≤0,045 | ≤0.03 | ≤1.00 | 16.0-18.0 | 6.0-8.0 | - |

| S30400 | 304 | 1.4301 | SUS304 | ≤0.08 | ≤2.00 | ≤0,045 | ≤0.03 | ≤0.75 | 18.0-20.0 | 8.0-10.5 | - |

| S30403 | 304L | 1.4306 | SUS304L | ≤0.03 | ≤2.00 | ≤0,045 | ≤0.03 | ≤0.75 | 18.0-20.0 | 8.0-12.0 | - |

| S30908 | 309S | 1.4833 | SUS309S | ≤0.08 | ≤2.00 | ≤0,045 | ≤0.03 | ≤0.75 | 22.0-24.0 | 12.0-15.0 | - |

| S31008 | 310S | 1.4845 | SUS310S | ≤0.08 | ≤2.00 | ≤0,045 | ≤0.03 | ≤1,50 | 24.0-26.0 | 19.0-22.0 | - |

| S31600 | 316 | 1.4401 | SUS316 | ≤0.08 | ≤2.00 | ≤0,045 | ≤0.03 | ≤0.75 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 |

| S31603 | 316L | 1.4404 | SUS316L | ≤0.03 | ≤2.00 | ≤0,045 | ≤0.03 | ≤0.75 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 |

| S31703 | 317L | 1.4438 | SUS317L | ≤0.03 | ≤2.00 | ≤0,045 | ≤0.03 | ≤0.75 | 18.0-20.0 | 11.0-15.0 | 3.0-4.0 |

| S32100 | 321 | 1.4541 | SUS321 | ≤0.08 | ≤2.00 | ≤0,045 | ≤0.03 | ≤0.75 | 17.0-19.0 | 9.0-12.0 | - |

| S34700 | 347 | 1.455 | SUS347 | ≤0.08 | ≤2.00 | ≤0,045 | ≤0.03 | ≤0.75 | 17.0-19.0 | 9.0-13.0 | - |

| S40500 | 405 | 1.4002 | SUS405 | ≤0.08 | ≤1.00 | ≤0.04 | ≤0.03 | ≤1.00 | 11.5-14.5 | ≤0.60 | - |

| S40900 | 409 | 1.4512 | SUS409 | ≤0.08 | ≤1.00 | ≤0,045 | ≤0.03 | ≤1.00 | 10.5-11.75 | ≤0.50 | - |

| S43000 | 430 | 1.4016 | SUS430 | ≤0.12 | ≤1.00 | ≤0,040 | ≤0.03 | ≤0.75 | 16.0-18.0 | ≤0.60 | - |

| S43400 | 434 | 1.4113 | SUS434 | ≤0.12 | ≤1.00 | ≤0,040 | ≤0.03 | ≤1.00 | 16.0-18.0 | - | - |

| S44400 | 444 | 1.4521 | SUS444L | ≤0,025 | ≤1.00 | ≤0,045 | ≤0.03 | ≤1.00 | 17.5-19.5 | ≤1.00 | - |

| S40300 | 403 | - | SUS403 | ≤0.15 | 5.5-7.5 | ≤0.04 | ≤0.03 | ≤0.50 | 11.5-13.0 | ≤0.60 | - |

| S410000 | 410 | 1.40006 | SUS410 | ≤0.15 | ≤1.00 | ≤0,035 | ≤0.03 | ≤1.00 | 11.5-13.5 | ≤0.60 | ≤1.00 |

| S42000 | 420 | 1.4021 | SUS420J1 | 0.16~0.25 | ≤1.00 | ≤0.04 | ≤0.03 | ≤1.00 | 12.0-14.0 | ≤0.75 | ≤1.00 |

| S440A | 440A | 1.4028 | SUS440A | 0,60 ~ 0,75 | ≤1.00 | ≤0.04 | ≤0.03 | ≤1.00 | 16.0-18.0 | - | ≤0.75 |

| S32750 | SAD2507 | 1.441 |

| ≤0.03 | ≤1.2 | ≤0,035 | ≤0.02 | ≤0.80 | 24.0-26.0 | 6.0-8.0 | 3.0-5.0 |

| S31803 | SAF2205 | 1.4462 |

| ≤0.03 | ≤2.0 | ≤0.03 | ≤0.02 | ≤1.00 | 21.0-23.0 | 4.0-6.5 | 2.5-3.5 |

| N08904 | 904L | 1.4539 |

| ≤0.0.3 | ≤2.0 | ≤0,035 | ≤0.03 | ≤1.00 | 18.0-20.0 | 23.0-25.0 | 3.0-4.0 |